Press Release

Outline of the Report on the Tunnel Ceiling Panel Collapse by the Investigation and Examination Committee

Accident Overview and Investigation by the Investigation and Examination Committee

○ At about 8:03 a.m. on Dec. 2nd, 2012, a continuous 140-meter-section of ceiling panels and partition walls, installed for tunnel ventilation in the Tokyo-bound Sasago Tunnel on the Chuo Expressway, collapsed. This resulted in two cars catching on fire inside the tunnel. Nine people were killed, and two others were injured. (Fire and Disaster Management Agency reported)

○ To understand the accident cause and to examine preventive measures for similar tunnels, the Investigation and Examination Committee for the Tunnel Ceiling Panel Collapse was launched and chaired by Dr. Toru Konda, emeritus professor at Tokyo Metropolitan University. After the first meeting on December 4th and with on-site surveys followed by in-depth examination, the Committee published a report on June 18th, 2013.

Note: The Committee does not intend to clarify where responsibility lies.

Specifications for Sasago Tunnel

○ The main body of the tunnel was completed in 1976, followed by the completion of ceiling panel installment and the opening of the tunnel in 1977.

○ A transverse ventilation system was adopted to provide sufficient ventilation for this tunnel, which was 4.4km long.

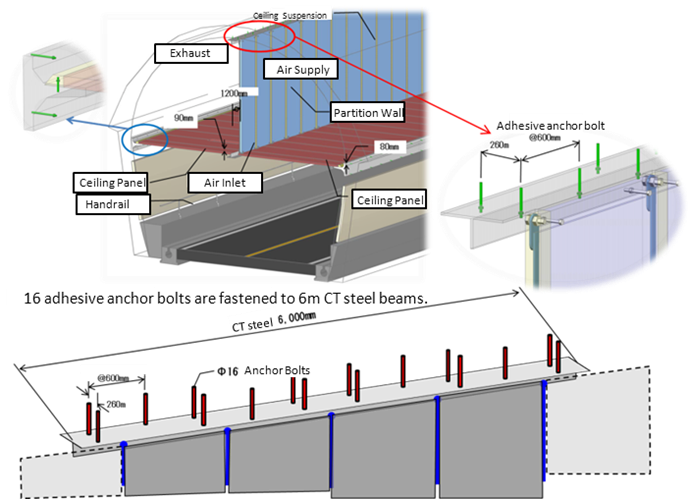

○ The cross-section of the tunnel was composed of partition walls and ceiling panels with three different dimensions (S, M, and L), depending on ventilation volume at each section. The partition walls and ceiling panels were supported by 16 adhesive anchor bolts and pedestals, which were anchored to 6m-long CT steel beams.

Presumptive Mechanism of Ceiling Panel Collapse and Accident Causes

With inspections and testing from a variety of aspects, including observation of the accident site, pull-out testing, working-form investigation, and aged deterioration investigation, a combination of the following factors that built up over time is thought to have caused this fatal accident.

○ Underlying factor that caused the accident from the design and construction stage

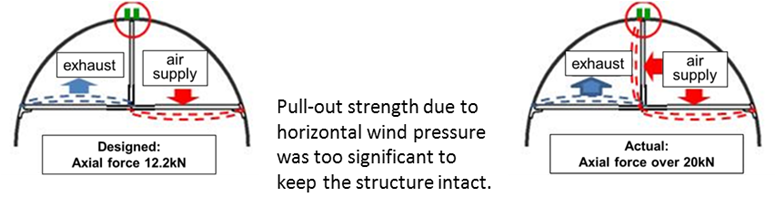

-The unique cross section of this accident site in the tunnel has very tall partition walls, which may have considerable pulling force on the ceiling adhesive bolts due to wind load on the partition walls in the horizontal direction. However, this pulling force was not considered in the initial tunnel design.

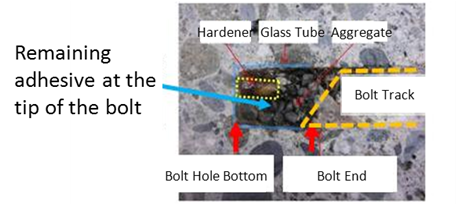

-There were inconsistencies among particular specifications, design reports, and final drawings, even though the length of anchor holes must correspond exactly to the length of bolt embedment. The investigation found a considerable number of anchor holes with remaining adhesive at the bottom because the bolt was shorter than the corresponding anchor hole. This means during the construction stage there were some bolts with insufficient pull-out strength.

-The catalog at the time of construction did not specify the application method for the adhesive bolt and said “there will be no deterioration or aging”.

【Cross Section of Core Sample】

○ There was deterioration or loss of pull-out strength due to load and material deterioration over a long period of time.

-Adhesive pull-out strength was deteriorating due to cracks and voids mainly developed by the following factors:

-Repeated load (stress amplitude due to on-and-off ventilation and wind pressure from passing vehicles)

-Material deterioration (hydrolytic degradation of adhesive)

○ Insufficient inspection and maintenance system before the accident

-There was no close visual inspection or hammer testing of the ceiling bolts in the L cross section for 12 years, because of a change of inspection plan without first clarifying the condition of the ceiling adhesive bolts.

Measures to Prevent Recurrence

(A circular notice that includes preventative measures was issued on March 29th, 2013.)

○ Existing suspended ceiling panels fastened with adhesive bolts which are subject to constant pulling force should be removed, where possible. If it is decided that the bolts are to be left in place, back-up structures and members should be installed.

○ Other heavy structures (e.g. jet-fans and road signs) fastened with adhesive bolts, which are subject to constant pulling force, should have back-up structures and members added to prevent possible damages to any third party.

○ As a fundamental rule, the use of adhesive bolts which are subject to constant pulling force should be avoided until a certain degree of knowledge is built up regarding long-term durability.

Desirable Design, Construction, and Maintenance

○ Long-term durability should be carefully examined before the application of new products.

○ Inspections should be conducted with the appropriate frequency, timing, and methods. Also, a system that records the history of inspections/repairs/reinforcements should be established and managed so that the information can be considered in any future inspections and other maintenance works.

○ A system that collects and shares information on failures should be established, while inspection manuals should be developed and design standards are updated adequately.

○ Development of new technologies is needed to realize appropriate road-related structure management.

July 19,2013