2.3. Port Information Measures

2.3.1 Standardization, simplification, and digitization of port-related procedures, and integration of systems of the relevant ministries and agencies

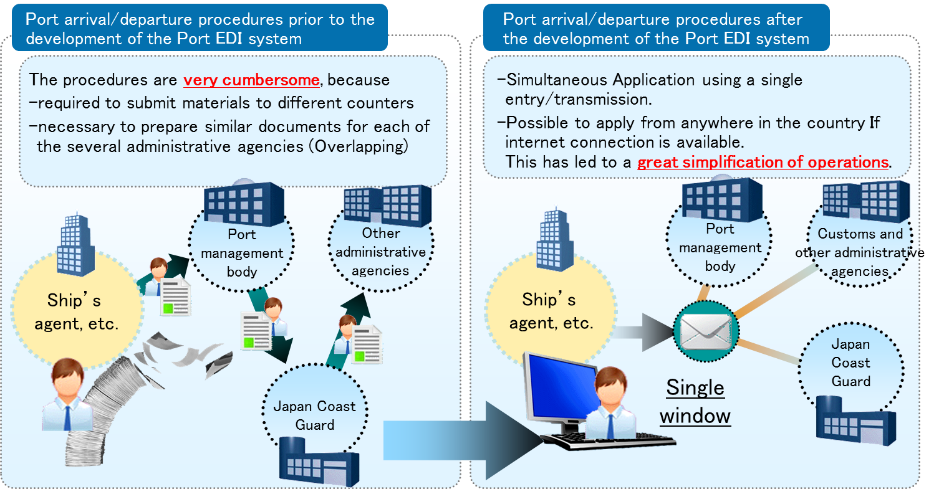

Since 1999, an electronic system for port-related procedures (Port EDI) has been in operation in Japan. In 2003, a single window system became available, that enables procedures related to the import/export of cargo and the entry/exit of vessels to/from the relevant administrative agencies with a single input and transmission by interconnecting and linking the various systems of the relevant ministries and agencies. In 2008, the port EDI and customs systems were integrated (hereinafter the integrated system will be referred to as "NACCS"*). To connect to systems for animal and plant quarantine, etc., a common portal for prefectural and municipal offices was established, and a single-window operation was further promoted. In 2013, systems for FAINS (Food hygiene), PQ-NETWORK (Plant quarantine), and ANIPAS (Animal quarantine) were integrated into NACCS, resulting in the centralization of the relevant government systems. From 2017, NACCS integration of port sub system has been implemented and operated as the 6th NACCS.

In addition, the FAL Convention (Convention on Facilitation of International Maritime Traffic) was signed in 2005, and the procedures themselves, including the port EDI system, were made compliant with the international standard FAL format for port access control procedures. Other procedures have also been standardized and simplified, and in October 2009, electronic applications for these procedures were made possible.

※ Nippon Automated Cargo and Port Consolidated System

Outline of Port EDI System

2.3.2 Construction of Cyber Port

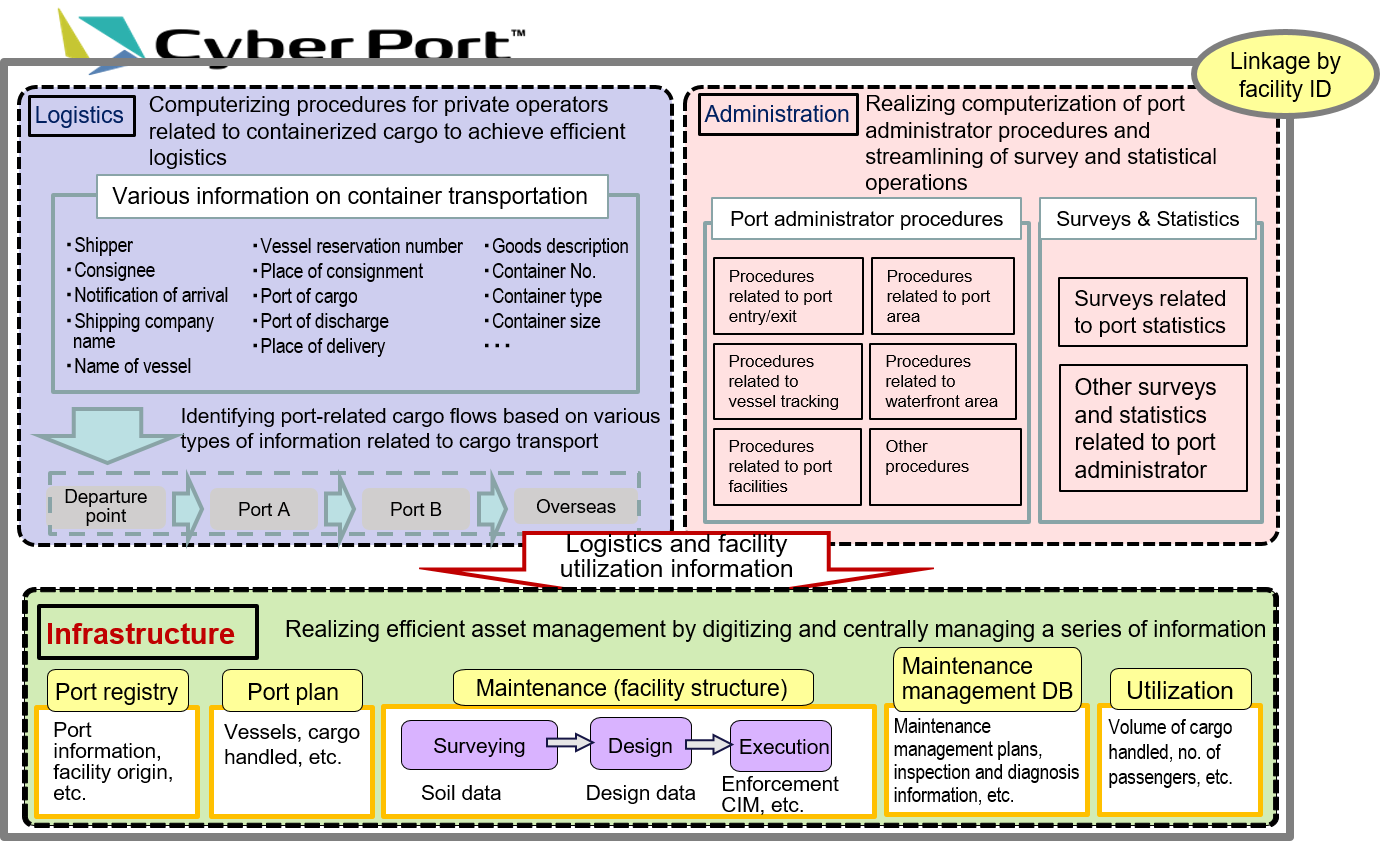

With the remarkable developments in information and communication technologies such as AI and IoT, international trade platforms have come into practical use. Additionally, digitization of procedures and the accompanying visualization of logistics have been promoted at ports in other countries. Thus, the trend toward digitization has been gaining momentum in various fields, and promotion of this trend in Japanese ports has become a requirement as well.

The productivity of Japan's ports will dramatically improve, and a business environment should be realized in which the various information surrounding ports are organically connected. To this end, efforts will be made to digitize port logistics procedures between private businesses(port logistics), port administrators' administrative procedures, surveys and statistics (port administration), and infrastructure information from port planning to maintenance and management (port infrastructure). Also, Cyber Port, a data platform that integrates and handles all of the above through data linkage, will be constructed.

2.3.3 Promotion of “i-Construction”

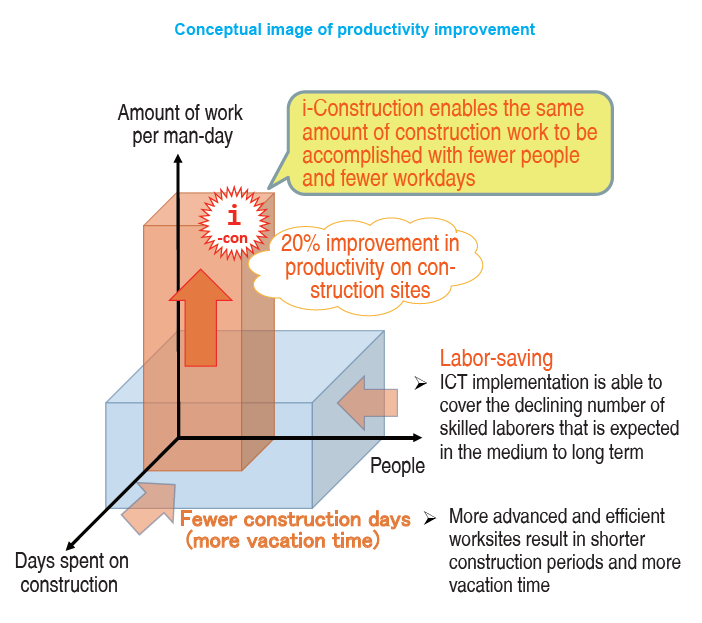

With the declining birthrate, aging society, and shrinking population, there are concerns about the shortage of labor in the construction industry in Japan. Amidst these circumstances, i-Construction, the use of ICT at construction sites, has been promoted toward the aim of achieving a 20% increase in productivity by FY2025. In 2020, efforts to accelerate DX (Digital Transformation) in the infrastructure sector have begun a shift toward non-contact and remote working methods and to radically improve productivity and safety, beginning from measures against the new coronavirus infections. As for ports, efforts have been made to further utilize ICT and BIM/CIM in port construction through discussions in the "i-Construction Promotion Committee for Ports," consisting of industry participants and experts.

Port construction projects often involve work at sea from surface vessels or underwater by divers. Thus, it is important to work as efficiently as possible when weather and sea conditions are favorable, as well as visualize the invisible undersea.

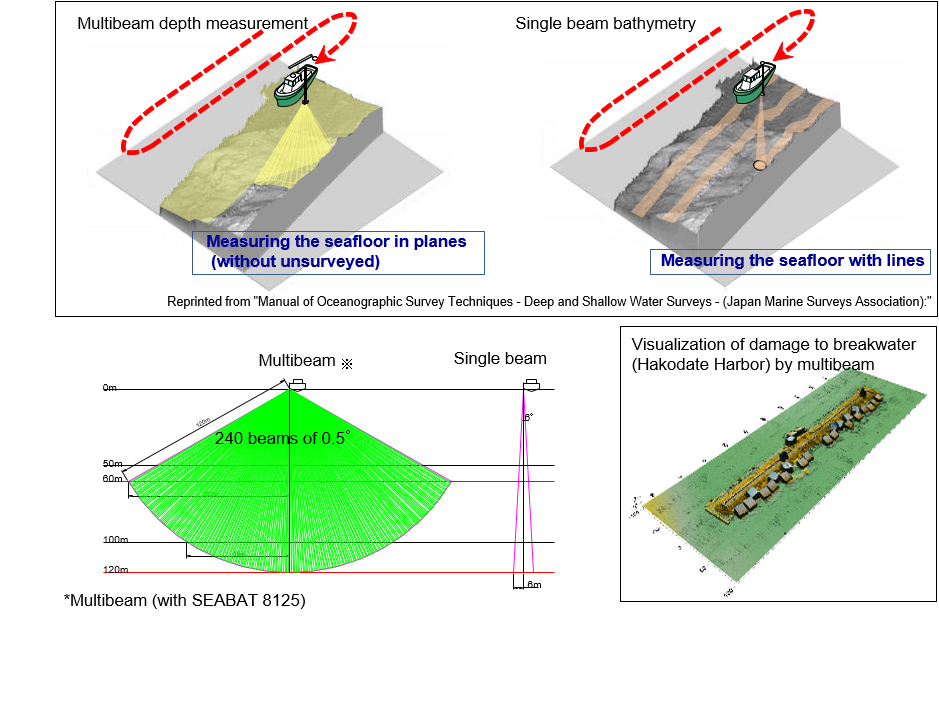

Considering the above, multibeam sonar (acoustic depth finder) has become the mainstay of field operations

in recent years. Conventionally, single-beam sonar, which can measure only the depth directly below the surface, or a lead-weighted string, have been used to determine and gauge seafloor conditions. Multibeam sonar acquires 3D data of the seafloor through forward movement of a vessel outfitted with equipment that emits numerous acoustic beams in the left/right directions, enabling an assessment of the overall condition of the seafloor. This makes the multibeam sonar indispensable in advancing ICT construction in port construction.

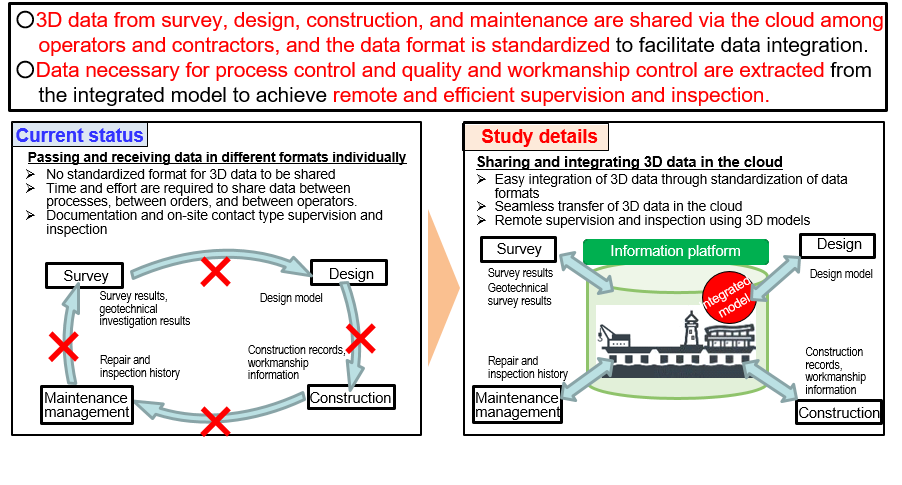

BIM/CIM (Building/ Construction Information Modeling, Management) has also been utilized, with 3D models used to check for component interference and safety, as well as for stakeholder consultations and construction explanations to the community. Furthermore, 3D data from surveys, designs, construction, and maintenance are registered on an information platform that can be shared among all parties involved. Utilizing the system for process control, quality and workmanship control, etc., it aims to realize remote supervision and inspection, as well as labor savings.