3rd Japan Construction International Award

Ministry of Land, Infrastructure, Transport and Tourism of Japan (MLIT) announced the third Japan Construction International Award winners on March 3, 2019. MLIT established “JAPAN Construction International Award (honored by the Minister of Land, Infrastructure, Transport and Tourism)” in 2017 to commend leading overseas construction projects as symbols of Japanese initiatives "quality infrastructure” which demonstrate Japan’s constructive contribution to the world. It also commends small and medium-sized construction companies which are playing leading roles in overseas markets.

Infrastructure needs is enormous in the world, including in Asian region. Japanese companies have been engaging in diverse projects of infrastructure design and construction, as well as real estate development, while fully demonstrating Japanese excellent design and construction know-hows and technologies, regardless of new business circumstances which are not the same in Japan. Such efforts have led to win unwavering trust from overseas clients, to contribute to capacity development and technology transfer, and thus, to provide quality infrastructure.

Construction Project Category

| PROJECT | COUNTRY | COMPANY |

|---|---|---|

| Waterview Connection Tunnels and Great North Road Interchange Project | New Zealand | Obayashi Corporation |

| Osman Gazi Bridge (Izmit Bay Bridge) Project | Turkey | IHI Infrastructure Systems Co., Ltd. |

| Sindhuli Road (Construction of Section III Phase 2 and Slope protection of Section II) | Nepal | Hazama Ando Corporation (Applicant) Nippon Koei (Design) |

Small and Medium-sized Construction Companies Category

| COMPANY | HQ LOCATION |

|---|---|

| GIKEN SEKO CO., LTD. | Kochi, Kochi prefecture |

| Helios Holding Co., Ltd. | Toyohashi, Aichi prefecture |

Construction Project Category

Construction Projects Category is for the best construction projects in which Japanese companies are participating outside Japan. For the 3rd Japan Construction International Award, projects completed after April 1, 2013 by March 31, 2018 are subject to the award.

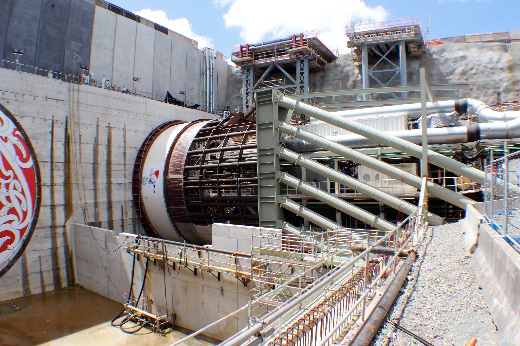

Waterview Connection Tunnels and Great North Road Interchange Project (New Zealand)

| PERIOD | Nov 2011 – Jun 2017 |

|---|---|

| PROCURING ENTITY | NZ Transport Agency (NZTA) |

| APPLICANT | Obayashi Corporation (https://www.obayashi.co.jp/en/) |

| MAJOR INVOVED COMPANIES | Design: Parsons Brinckerhoff (present WSP), BECA, Tonkin & Taylor Construction: Obayashi, Fletcher Construction, McConnell Dowell |

Overview:

- One of the largest transport infrastructure project in New Zealand: 2400m twin shield tunnels connected missing link in the circular highway in Auckland. This project has eased traffic congestion and improved airport access, with over 60,000 daily traffic.

- New Zealand’s first large section shield tunnel (14.5m of bored diameter)

- Adopting alliance contract where the owner, designers and contractors join the alliance to execute the project and Obayashi participated in critical decision-makings as well as tunnel design, construction management and risk management of tunneling.

Key points:

- To minimize Life-cycle cost, The tender is assessed by combination of two bids, design & build of highway and 10 years operation and maintenance. The awarded party executes two contracts under alliance. It enhanced Japanese business's capability for public-private collaborated partnership.

- Stakeholder management has been well addressed such as protection of natives’s relic, Maori art element at tunnel portal, pedestrian bridge designed reflecting local voices and construction of various facilities to provide local community for entertaining.

- Experience of large diameter EPB Shield tunnel under shallow overburden allows to change tunnel design from conventional SEM planned as original to precast lined TBM. 2500t TBM made a U-turn after the first tunnel without dismantle/reassembly in order to reduce construction period and cost, which is also one of examples to utilize application in Japan .

Osman Gazi Bridge (Izmit Bay Bridge) Project (Turkey)

| PERIOD | Jan 2013 - Jun 2016 |

|---|---|

| PROCURING ENTITY | NOMAYG JV (Subsidiary of PPP investors) |

| APPLICANT | IHI Infrastructure Systems Co., Ltd. (https://www.ihi.co.jp/iis/en/index.html) |

| MAJOR INVOLVED COMPANIES | Design / Construction: IHI Infrastructure Systems Co., Ltd. |

Overview

- Construction of the bridge crossing Izmit Bay in the motorway from Istanbul to Izmir (third largest city in Turkey). It is the first highway with a BOT (build-operate-transfer) scheme in the country.

- Contribution to the development of the south-western part of Turkey: trans-bay travelling time was shortened from 1 hour (by ferry) or 1.5 hours (by land) to only 6 min by crossing the bridge, and total travelling time from 9 hours to 4.5 hours with 420km of the new highway.

- Global record of construction speed for a long suspension bridge: the bridge, with a total length of 2,682m and a center span of 1,550m (the 4th longest in the world) was completed in only 48 months.

Key points

- Life-cycle cost reduction: bridge dehumidification equipment, electric corrosion protection, using stainless steel to splashing zone, early recognition of abnormality by 24h remote monitoring in the operation in order to prolong bridge’s lifespan. Making tailor-made design standard in accordance with the performance requirement realized cost-minimum.

- World’s first bridge features: aseismic base isolation system of the main tower as a counter-earthquake measure, active vibration control device used in the bridge operation as a counter-wind measure.

- Various business contribution including adaptation to the business with private procuring entity in the BOT model to succeed the project.

Sindhuli Road (Construction of Section III Phase 2 and Slope protection of Section II) (Nepal)

| PERIOD | Jul 2012 – Mar 2015 |

|---|---|

| PROCURING ENTITY | Department of Road, Ministry of Physical Infrastructure and Transport, Nepal |

| APPLICANT | Hazama Ando Corporation (http://www.ad-hzm.co.jp/english/index.html) |

| MAJOR INVOLVED COMPANIES | Design: Nippon Koei (https://www.n-koei.co.jp/english/) Construction: Hazama Ando |

Overview

- Section III Phase II is the last part of a 160 km long mountainous road construction connecting Kathmandu, Nepal’s capital, with Indian border funded by Japanese Governments’ Grant. Slope protection was implemented as remedy to the collapsed slope caused by heavy rain.

- Accelerated work in spite of the socio-political difficulties: one month delay caused by political turmoil and other problems such as local sabotage was fixed with efforts including dividing working sections and additional deployment of equipment and workers.

-

Technology transfer from Japan for disaster prevention on road: Japan’s well proven technologies have supported the sustainable development of Nepal, where 80% of the land is mountainous.

Key points

- Resiliency proved by the Gorkha Earthquake on April 25, 2015 (magnitude 7.8): despite unfavorable geotechnical condition, this road maintained traffic due to the design with high durability against natural disasters while many other major routes were disconnected. People appreciated this road as a major route for relief goods transport.

- Maximum social consideration measures were adopted in the response to local residents’ demanding activities and relocation issue. Applicant maintained thoughtful consultations with local politicians and government officials even in the politically and socially chaotic situation. Affected residents with no-experience were hired as construction workers which the applicant supported by systematic safety management.

- The officer in charge from Nepal Government appreciated the technologies transferred from Japan such as slope stabilization and retaining wall as technologies which should be utilized for future road construction in the country.

Small and Medium-sized Construction Companies Category

Small and Medium-sized Construction Companies Category is for the Japanese leading Small and Medium-Seized Enterprises (SMEs) in construction industry operating world wide.

GIKEN SEKO CO., LTD.

| LOCATION | Kochi, Kochi prefecture |

| CAPITAL | 30 million JPY |

| NUMBER OF EMPLOYEE | 134 |

| BUSINESS DESCRIPTION | Civil Engeneering Work,Consulting Service,Construction Supervision, etc. |

| OVERSEAS BUSINESS | Senegal, Egypt, Bangladesh, Singapore, Philippines, etc. |

| WEBSITE | https://www.gikenseko.co.jp/ (Japanese) |

Company Features

Developing business all over the world mainly with “Press-in Method”, that enables to press-in piles with low vibration, low noise, space saving and safety.

Overview of Overseas Business and Evaluation Points

- In 1983, GIKEN SEKO exhibited “Silent Piler”, a press-in method machine developed in-house, at the exhibition in Germany. Because the features of the machine were evaluated at that time, GIKEN SEKO received an order which is the first construction overseas in the same year. Since then, GIKEN SEKO has developed business with the press-in method in more than 30 countries.

- GIKEN SEKO conducts employee training before assigns them abroad. In the training, all of them thoroughly learn how to respond to emergencies such as disasters. This training have led to solid risk management.

- In 2019, Press-in Method Training Center was established in Japan. GIKEN SEKO is going to accept trainees from domestic and foreign at this facility, and transfer technologies such as repairing, maintenance and operation of the press-in machine to them.

Silent Piler |

Construction in Senegal |

Press-in Method Training Center |

Recent Record

Overseas sales

| FY | Amount |

| 2017 | 565 million JPY |

| 2018 | 206 million JPY |

Recent major contract

| Country | Project | Procuring Entity | Amount | Period |

| Senegal | Project for Rehabilitation of the Third Wharf in Dakar Port | Port Autonome de Dakar | 720 million yen | 2019.5 ~2020.6 |

| Egypt | Project for Construction of Outpatient Facility at Cairo University Specialized Pediatric Hospital |

Cairo University | 42 million yen | 2019.5 ~2019.10 |

| Bangladesh | Kanchpur, Meghna and Gumti 2nd Bridges Construction and Existing Bridges Rehabilitation Project |

Roads and Highways Department, Ministry of Road Transport and Bridges of Bangladesh |

798 million yen | 2016.11 ~2017.10 |

Helios Holding Co., Ltd.

| LOCATION | Toyohashi, Aichi prefecture |

| CAPITAL | 30 million JPY |

| NUMBER OF EMPLOYEE | 150(Overseas: 100) |

| BUSINESS DESCRIPTION | Meter infrastructure |

| OVERSEAS BUSINESS | Senegal, Egypt, Bangladesh, Singapore, Philippines, etc. |

| WEBSITE | https://www.helios.jp/home-1 |

Company Features

Promoting installation of quality gas meter for prepaid supply in Bangladesh and other countries.

Overview of Overseas business and Evaluation Points

-

To solve the over-consumption of city gas in Bangladesh, the company introduced pre-paid gas meter to the country. The company is working on the installation of total 260 thousand meters under the JICA’s proposal-based pilot project and Yen Loan project.

- The company briefed Bangladesh’s gas supplier on the benefit of the Japanese gas meter. In the bidding process, high evaluation on the Japanese gas meter’s quality was the key factor to win the contract.

-

Prepaid meter system is customized to accommodate local market condition. For example, IC card and/or mobile payment could be used as the payment system.

Pre-paid gas meter and installation in Bangladesh |

Local workers in Bangladesh |

Recent Record

Overseas sales

| FY | Amount |

| 2017 | 1.06 billion JPY |

| 2018 | 2.13 billion JPY |

Recent major contract

| Country | Project | Procuring Entity | Amount | Period |

| Bangladesh | Prepaid gas meter installation for TGTDCL | Titas Gas Transmission & Distribution Company Limited(TGTDCL) |

5.4 billion yen | 2017.3 ~2020.3 |

| Bangladesh | Prepaid gas meter installation for KGDCL | Karnaphuli Gas Distribution Company Limited (KGDCL) |

1.6 billion yen | 2017.1 ~2019.12 |