3rd Japan Construction International Award

Construction Project Category

Waterview Connection Tunnels and Great North Road Interchange Project [New Zealand]

Project overview

- The country’s largest transportation infrastructure project, connecting the unfinished highway section of Auckland, New Zealand’s central city, with two shield tunnels of 2,400 meters. More than 60,000 vehicles use it a day, which greatly contributed to easing traffic congestion in the city and improving airport access.

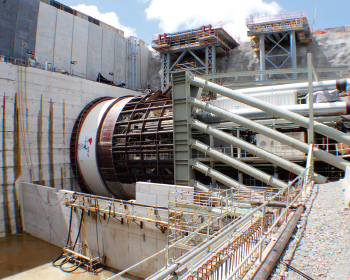

- The company successfully reduced costs and avoided affecting third-party traffic by using New Zealand’s first large-section shield tunnel (drilling diameter: 14.5m) via a transfer of skills from Japan.

- General clients, designers and contractors formed an alliance in New Zealand, and based on an alliance agreement to execute the project, OBAYASHI CORPORATION participated in examining and approving important matters relating to the entire operation, as well as in shield tunnel design, construction planning, construction management and risk management.

Data

Period:From November 2011 to June 2017

Procuring Entity:New Zealand Transport Agency(NZTA)

Applicant:OBAYASHI CORPORATION

Relevant Companies

Design:Parsons Brinckerhof(f WSP), BECA, Tonkin & Taylor

Construction:OBAYASHI CORPORATION,Fletcher Construction, McConnell Dowelll

Evaluation points

- The company bid on the project via a bidding method that considers not only design and construction but also life cycle costs, including the monetary value of maintenance work after ten years of service. The company continued to participate in maintenance under an agreement allowing maintenance to be subcontracted as a bidder’s option. In addition to embodying Japanese quality infrastructure, the company achieved results in joint projects between the public and private sectors, which have been lagging.

- The company was awarded by the client for its consideration toward the community, such as preserving indigenous remains, incorporating indigenous artistic elements into the tunnel entrance design, listening to local opinions on footbridge design, and developing resident restoration facilities.

- Although it was originally designed using the method for constructing mountain tunnels, the project used the shield tunnel method due to a proposal from a Japanese company. After completing the first drill-through, the 2,500t shield machine was turned around and immediately began the second drill-through without disassembly and reassembly, which reduced construction time and costs.

Osman Gazi Bridge (Izmit Bay Bridge) Project [Turkey]

Project overview

- Bridge construction over the Gulf of Izmit on the highway connecting Istanbul and Izmir, Turkey’s third largest city, in Turkey’s first BOT road project that includes a bridge.

- The construction of the bridge reduced the travel time of the section, which took an hour by ferry and about 1.5 hours by land in the Gulf, to 6 minutes, greatly contributing to the development of southwestern Turkey by reducing travel time (9 hours → 4.5 hours) through the construction of a 420km highway.

- The 2682 meter-long suspension bridge was completed in just 48 months, recording the world’s No.1 construction speed as a long suspension bridge.

Data

Period:From January 2013 to June 2016

Procuring Entity:NOMAYG JV (Construction and Construction Supervision Corporation by Companies Participating in PPP Business)

Applicant:IHI Infrastructure Systems Co., Ltd.

Relevant Companies

Design:IHI Infrastructure Systems Co., Ltd.

Construction:IHI Infrastructure Systems Co., Ltd.

Evaluation points

- Life cycle costs were reduced by using stainless steel in the bridge’s dehumidification equipment, electric anticorrosion equipment, and locations subject to water spray, as well as by early identification of abnormalities through constant monitoring via a remote monitoring system after delivery. Costs were kept to a minimum by formulating unique design standards in line with the desired performance.

- As an earthquake countermeasure, the main tower of the suspension bridge makes use of the world’s first seismic isolation structure. The structure was successfully created through strict construction management. As a wind countermeasure, the bridge makes use of the world’s first active vibration suppression device in service in a suspension bridge.

- In addition to a short construction period and low life cycle costs, the order was received after beating out the competitors by advantageously promoting EPC contract order competition after bidding for project rights, thanks to the cooperation of BOT road operators from the bid preparation stage.

Sindhuli Road Project (Construction on Section Ⅲ and Countermeasure Construction against the Landslides on Section Ⅱ ) [Nepal]

Project overview

- Final construction in a difficult section along a river and slope reinforcement construction on sections of slope that collapsed due to heavy rains along a roughly 160km-long mountain road built using grant money from Japan as an alternative to the existing road from Kathmandu, the capital of Nepal, to the Indian border.

- Although construction was delayed for about a month due to political turmoil, etc., ultimately all road lines were successfully opened ahead of schedule via efforts to limit the impact of construction interruptions due to the construction area being split up as well as investment of additional equipment and personnel.

- Road disaster prevention technology, in which Japanese companies are superior, was utilized and transferred in Nepal, where 80% of the national territory is mountainous.

Data

Period:From July 2012 to March 2015

Procuring Entity:Government of Nepal Ministry of Physical Infrastructure and Transport, Department of Road

Applicant:HAZAMA ANDO CORPORATION

Relevant Companies

Design, Construction Supervising:Nippon Koei Co., Ltd.

Construction:HAZAMA ANDO CORPORATION

Evaluation points

- The 7.8-magnitude Gorkha earthquake, which occurred on April 25, 2015, closed most of the major roads throughout Nepal, but Sindhuli Road remained open and was considered a great route for transporting relief supplies due to its structure that is highly resilient to natural disasters even considering the region’s fragile ground conditions.

- Even amidst the political and social turmoil, maximum social consideration was given in cooperation with government officials in responding to request activities from residents and in the issue of relocating residents. And although they lacked experience, residents affected by the construction were employed as civil engineering workers under careful safety management.

- Various slope stability and retaining wall construction techniques introduced at the time of construction were highly praised by the Nepalese government officials in charge who said, “These techniques should be put to use in future road construction.”