6th Japan Construction International Award

Construction Project Category

- Hanoi - Ho Chi Minh City Railway Line Bridges Safety Improvement Project (CP1D,CP2,CP3A) [ Socialist Republic of Viet Nam ]

- The Project for Reconstruction of Vaisigano Bridge [ Independent State of Samoa ]

- The Project for Improvement of Ghanaian International Corridors (Grade Separation of Tema Intersection in Tema) [ Republic of Ghana ]

- The Kanchpur, Meghna and Gumti 2nd Bridges Construction and Existing Bridges Rehabilitation Project (KMG) [ People’s Republic of Bangladesh ]

- BRANZ BSD [ Republic of Indonesia ]

Hanoi - Ho Chi Minh City Railway Line Bridges Safety Improvement Project (CP1D,CP2,CP3A) [ Socialist Republic of Viet Nam ]

Project overview

- Rehabilitation project for the North-South Railway line between Hanoi and Ho Chi Minh, which is Vietnam’s principal railway line.

- Reconstruction of 23 bridges, improvement of railway tracks (use of heavy-duty rails and PC sleepers) and double-tracking of part of the line have made possible a faster, more punctual and more stable railway service.

- While transferring maintenance techniques for government officials, national railway employees and local engineers, efforts have been underway to expand into other projects in neighboring countries as well, leveraging the construction framework built through this project.

Data

Period:From May 2010 to May 2016

The Employer:Vietnam Railways

Applicant:TEKKEN CORPORATION

Relevant Companies

Architect:CHODAI CO., LTD. /ORIENTAL CONSULTANTS CO., LTD. /JAPAN INTERNATIONAL CONSULTANTS FOR TRANSPORTATION CO., LTD.

Construction:TEKKEN CORPORATION, Yokogawa Bridge Corp., Thang Long Construction Corporation JV(CP1D)/ TEKKEN CORPORATION, Yokogawa Bridge Corp., Thang Long Construction Corporation, Marubeni Corporation JV(CP2)/TEKKEN CORPORATION, MITSUI E&S Co., Ltd., Thang Long Construction Corporation JV(CP3A)

Evaluated points

- The in-situ replacement method, which is Japan’s specialty, was employed for 22 of the 23 bridges. This made it possible to replace the bridges while keeping trains in service.

- Efforts were made to develop human resources and transfer techniques. These include teaching skills in railway construction and maintenance directly to local engineers and workers, hiring new graduates from local schools and sending competent engineers of the local cooperative company to Japan as technical intern trainees.

- TEKKEN CORP. has taken part in railway projects in Myanmar and Bangladesh as well, leveraging the relationships that it has built with the local cooperative company and others through this project and other activities including investing in the local cooperative company.

The Project for Reconstruction of Vaisigano Bridge[ Independent State of Samoa]

Project overview

- This is a project for the reconstruction of the Vaisigano Bridge located on the major highway connecting Fagali'i Airport and Apia Bay, the only commercial port in Samoa.

- Taking into account the salt damage to the old bridge and large-scale disasters due to climate change and other factors, the project team chose salt corrosion-resistant materials and construction methods for the new bridge. They also formulated bridge specifications high enough to withstand extensive natural disasters, giving the new bridge a longer service life and increased robustness.

Data

Period:From March 2018 to January 2021

Client:Land Transport Authority, The Independent State of Samoa

Applicant:KONOIKE CONSTRUCTION CO.,LTD.,Central Consultant Inc.

Relevant Companies

Design:Central Consultant Inc.

Construction:KONOIKE CONSTRUCTION CO.,LTD.

Evaluated points

- Since the old bridge had been degraded due to salt damage, salt corrosion-resistant materials and construction methods were chosen for the new bridge with the aim of extending the bridge service life.

- Given the increased risk of the old bridge collapsing due to the major cyclone in 2012, the new bridge has high specifications enough to withstand an extensive natural disaster that may take place during the next 100 years.

- All the subcontractors engaged in the project work were Samoan companies, with Japanese workers assigned to bridge construction and other highly specialized work. Pre-tension hollow slabs were producted at the project site to enable local engineers to produce girders themselves through technology transfer, as well as to avoid unstable seaborne procurement.

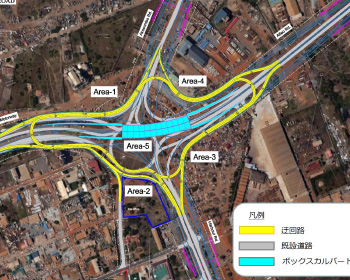

The Project for Improvement of Ghanaian International Corridors (Grade Separation of Tema Intersection in Tema)[ Republic of Ghana]

Project overview

- This project was aimed at improving the Tema intersection where two international corridors cross. One is Route 1, which runs east-west through Accra, the nation’s capital, suffering from chronic traffic congestion because of the recent increase in traffic volume. The other is the Eastern Corridor running south-north from Tema Port to the eastern part of Ghana.

- Building an underpass for the new intersection based on meticulous construction and safety plans has contributed to promoting smooth logistics.

Data

Period:From February 2018 to June 2020

Procuring Entity:Ghana Highway Authority, Republic of Ghana

Applicant:SHIMIZU-DAI NIPPON JV

CTI Engineering International Co., Ltd.

Relevant Companies

Design:CTI Engineering International Co., Ltd.

Construction:SHIMIZU-DAI NIPPON JV

Evaluated points

- To secure a work zone for the construction of the underpass, a plan that required only one detour was implemented. This helped not only to avoid confusion stemming from the construction work (congestion and other dangerous situations) but also to ease traffic congestion compared to before the work started, even during the period of detouring.

- Aerial imagery captured by drones was used to share with the procuring entity the information about the progress of work and problems such as delays arising from the acquisition of land or the relocation of underground pipes by the procuring entity. This enabled the construction to progress smoothly.

- The use of CIM for concrete work made it easier to imagine even complex chassis shapes and increased understanding among those concerned. This also resulted in fewer reinforced bar assembling and formwork errors, reduced rework, and quicker inspections. Improvement in productivity contributed to completing the construction work safely on schedule while maintaining a stable level of quality.

The Kanchpur, Meghna and Gumti 2nd Bridges Construction and Existing Bridges Rehabilitation Project (KMG)[ People’s Republic of Bangladesh]

Project overview

- This is an all-Japan project for the rehabilitation of the Kanchpur, Meghna and Gumti Bridges located on National Highway No. 1 connecting Dhaka and Chittagong, as well as for the construction of new bridges running parallel to these existing bridges.

- The new bridges have increased the traffic capacity from 17,000 vehicles per day to 50,000 vehicles per day. Developing special economic zones in the surrounding areas is expected to create a total of 10 million jobs.

- The new bridges construction and existing bridges rehabilitation has made the existing bridges safer and dealt with the rapidly increasing traffic demand, contributing to vitalizing the Bangladesh economy as a whole.

Data

Period:From January 2016 to January 2020

Procuring Entity:People’s Republic of Bangladesh Roads and Highways Department, Ministry of Road Transport and Bridges

Applicant:Obayashi Corporation/SHIMIZU CORPORATION/ JFE Engineering Corporation/IHI Infrastructure Systems Co., Ltd. JV/Oriental Consultants Global Co., Ltd./Japan Bridge & Structure Institute, Inc./Katahira & Engineers International/ NIPPON ENGINEERING CONSULTANTS CO., LTD. JV

Relevant Companies

Design:Oriental Consultants Global Co., Ltd./Japan Bridge & Structure Institute, Inc./Katahira & Engineers International/NIPPON ENGINEERING CONSULTANTS CO., LTD./SMEC International JV

Construction:OBAYASHI CORPORATION/SHIMIZU CORPORATION/ JFE Engineering Corporation/IHI Infrastructure Systems Co., Ltd. JV

Evaluated points

- A number of Japanese construction technologies have been introduced and transferred, including the adoption of the steel pipe sheet pile (SPSP) foundation to prevent river bed scouring, use of steel narrow box girders and steel concrete composite deck slabs and continuous bridge hinges with PC outer cables.

- Low-noise equipment was used for dust and noise reduction, and cast in-situ piles construction method that does not use bentonite as a stabilizing solution were adopted to prevent water pollution. Environment-conscious measures were taken, such as suspending the work temporarily when river dolphins were spotted.

- The safety of workers and local residents was protected by adopting safety standards equivalent to those in Japan, including installing concrete barriers and traffic signs and providing appropriate vehicle and pedestrian ways.

BRANZ BSD[Republic of Indonesia]

Project overview

- This is a real-estate development project for providing environment-conscious smart residences in Indonesia by leveraging housing development experiences in Japan ranging from land acquisition to design, sale, construction, handover, operation and management.

- The plan was implemented with the building management company from the design stage, taking into consideration improved maintainability and cost reductions.

- Through condominium development projects, PT. Tokyu Land Indonesia is highly regarded by local people, becoming the only foreign company that has been selected as one of Indonesia's top 10 developers twice.

Data

Period:From August 2015 to October 2018

Applicant:TOKYU LAND CORPORATION/PT.TOKYU LAND INDONESIA/NIKKEN SEKKEI LTD/NIKKEN HOUSING SYSTEM LTD/NIKKEN SPACE DESIGN LTD/ PT.TOKYU PROPERTYMANAGEMENT INDONESIA

Relevant Companies

Architect:PT.ANGGARA ARCHITEAM

Offshore Consultants:NIKKEN SEKKEI LTD/NIKKEN HOUSING SYSTEM LTD/NIKKEN SPACE DESIGN LTD

Construction:PT. Nusa Raya Cipta (General Contractor)/ PT. SHINRYO INDONESIA (Mechanical, Electrical and Plumbing)

Management company:PT.TOKYU PROPERTY MANAGEMENT INDONESIA

Evaluated points

- The company has developed a long-term, continuous supply of quality housing, starting with a detached house business developed jointly with local capital in 1975. In this development, a long-term repair plan, which is not yet common in Indonesia, was introduced to maintain and improve property values over the medium to long term.

- The adoption of a maintainability-focused drainage system and the use of industrial-grade products such as precast concrete expected to provide uniform quality, among other things, offer a high level of quality in Indonesia.

- The use of Low-E glass with high heat shielding performance and Japanese-made LED lamps reduces power consumption and, consequently, environmental impact.

- Contributing community-based activities, such as holding free COVID-19 vaccination events for local residents after construction was completed.